Remember, beginners – relax, take your time, and enjoy the process. When programming a 5-axis toolpath using a CAM system, the software will automatically.

I read ALL of the messages I get through my website, and I answer as many as humanly possible – unless you’re a spambot. Tool vectors can also make post processor creation easier as well.

#VECTOR CNC SOFTWARE PRO#

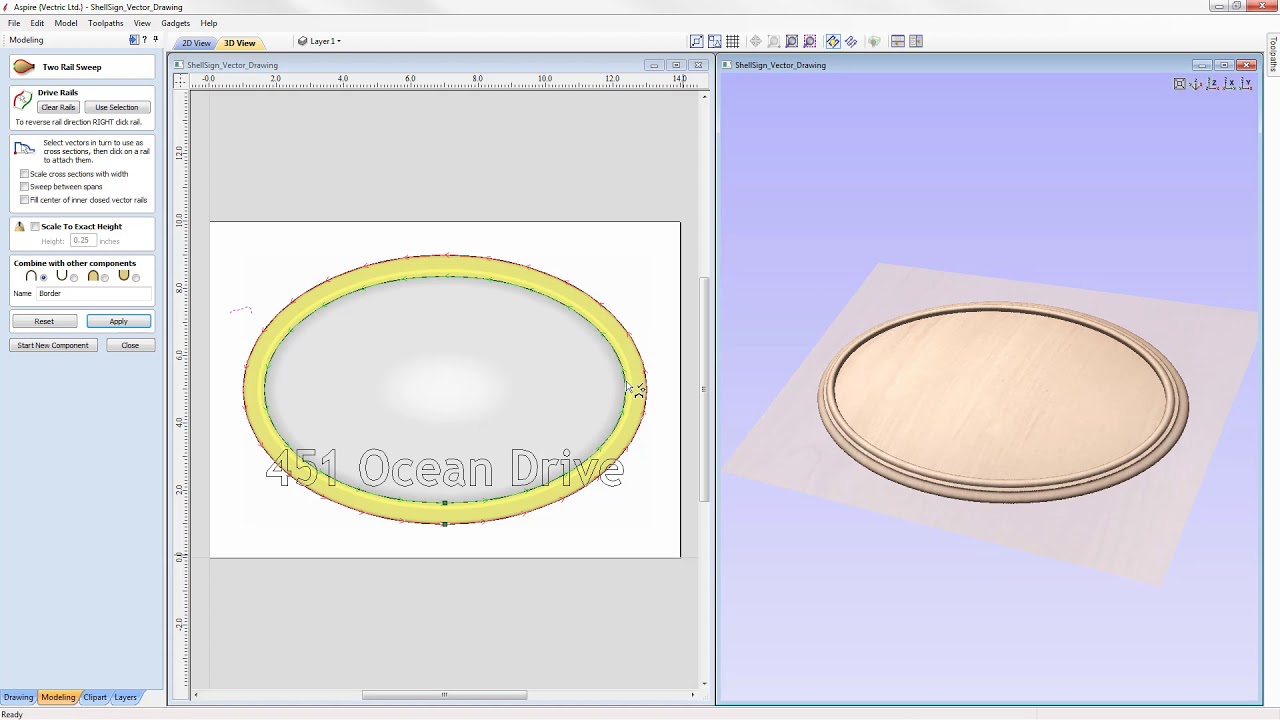

I use Aspire version 10.019 in this video, but all of the information in the video applies to Cut 2D (both the Desktop and the Pro versions,) VCarve (both the Desktop and the Pro versions,) and Aspire software.Īs usual, if you have any questions, comments, or concerns, please feel free to comment! If you don’t wish to make a public comment, click this Contact Us link, and submit it to me privately. Below is a link to the 42nd video in the series that’s geared toward the absolute Vectric software beginner.

#VECTOR CNC SOFTWARE HOW TO#

You don’t’ have to cut anything with it – it’s more important that you learn how to use the software than it is to start making chips. Get into your CAD/CAM software, and learn it.

Just like anything else you want to do, there is no replacement for experience – and the only way to get that experience is to practice. Then they are converted into the vector and 3D file formats. Aspire is an easy to learn and elegant solution to the complex job of designing and machining 2D, 2.5D and 3D parts with a CNC machine. The designs we have prepared are drawn manually in 2D CAD software. It’s not always super easy, but it’s never really super difficult, either. Aspire is Vectric's top-of-the-line and most feature packed CNC software solution to date. It’s supposed to be fun, remember? You CAN learn this.

0 kommentar(er)

0 kommentar(er)